Why is Calibration Important?

You wouldn’t measure sea surface temperature with a meat thermometer. Likewise, you wouldn’t use an SBE 3 to check a steak. There are some obvious reasons for this, primarily related to hardware, cost, and design, but ultimately meat thermometers just aren’t calibrated for the job. No matter how skillfully engineered a sensor may be, its data is only as good as its calibration. Our heritage of world-class calibration facilities make sensors from Sea-Bird Scientific exceptionally accurate, and our robust engineering keeps them that way.

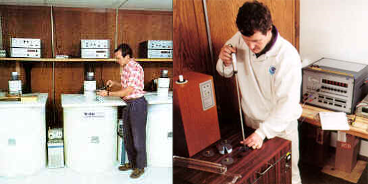

Sea-Bird’s early calibration and metrology labs.

Calibrating for Accuracy

If your sensor is only as good as its calibration, your calibration is only as good as the standard to which it is referencing. Although Sea-Bird Scientific sensors are often used as the calibration standard for other instruments, we rely on NIST-traceable laboratory standards that achieve greater accuracy. For example, our primary temperature standards are the triple point of water and gallium melt point, achieving calibration bath accuracy better than 0.0005 °C (for reference, SBE 3 temperature sensor field accuracy spec is ± 0.001 °C). With this degree of accuracy, manufacturers of less accurate instrumentation can rely on our sensors to act as their laboratory standard.

Engineering for Precision and Stability

After calibration, sensor technology and design become the limiting factor. After all, a controlled laboratory setting is a different world from the rigors of a field deployment. The moment that a sensor leaves the calibration bath it begins to drift, and environmental conditions may accelerate this drift. Oceanographic sensors therefore require a robust design with sources of drift that are well characterized and minimized, and the accuracy specifications need to account for that. Field data and laboratory experiments at Sea-Bird, such as those involving freezing Argo CTDs, showcase how sensor calibration is not compromised by harsh field conditions.

Field Calibrations

Many commercially available sensors can be calibrated in the field with pre-packaged standard solutions like pH buffer solutions and conductivity standards. For Sea-Bird Sensors, “correction” in the field is a more accurate term than “calibration”. Recall that your data is only as good as your calibration, and since the open ocean can’t replicate the carefully controlled conditions of the calibration laboratory, corrective actions in the field are liable to add measurement error and uncertainty. Furthermore, many standard solutions are less accurate that data from the sensor itself – a given conductivity standard solution may be accurate to 0.001 S/m, while the SBE 4 sensor has an initial accuracy of 0.0003 S/m. That said, CTDs are often deployed alongside a water sampler, and water samples analyzed in a reliable laboratory can provide acceptable corrective data. Data from Winkler dissolved oxygen analysis and salinity from an autosal, especially if the sample originated in stable deep ocean water, can help correct for small measurement errors.

Related Posts

Featured Posts

Oceanology International 2024

We hope to see you at #Oi24 We are excited to return to Oceanology International 2024 again in London, UK from March 12-14. Overview Oceanology International brings together 500+ exhibitors in the only event that links the three key players in the industry:...

Ocean Sciences Meeting 2024

We hope to see you at #OSM24 We are excited to return to Ocean Sciences Meeting 2024 in New Orleans, Louisiana from February 18-23 at booth number #527. Overview The Ocean Sciences Meeting 2024 is co-sponsored by the American Geophysical Union, the Association for the...

Pride 2023

Celebrating and honoring our LGBTQIA+ communities At Sea-Bird Scientific, we are proud to stand with members of the LGBTQIA+ community during Pride Month 2023. As with last year, we changed our logo on social media to feature a rainbow throughout the month of June in...

Science and Technology

Platform