Frequently Asked Questions

Software & Data Processing

Unfortunately, users cannot currently program their SUNA to start at a preferred time. As soon as the SUNA is powered, the instrument will begin it’s programmed sampling mode on the hour. Users can use the offset feature to change the start time. For example, an offset value of 300 (5 min) changes the start time by five minutes, for example, from 06:00 to 06:05.

The continuous mode setting allows the user to program their SUNA to run continuously for an indefinite amount of time. When power is supplied to the SUNA, it will start data acquisition without an end time or maximum number of frames to measure. In general, we do not recommend this mode for long periods of time because the lamp of the SUNA can burn out. As a general rule of thumb, the SUNA lamp should be replaced when it reaches 750 hours.

The periodic mode setting allows the user to select how often, and how long sample intervals are based on frame-based or time-based operation.

For example, if a user would like to program their SUNA to sample every two hours, they would use a sample interval of two hours.

The user would then select either frame-based or time-based operation

For frame-based operation, the user selects the number of light frames the SUNA will sample for.

For time-based operation the user selects how many seconds of light frames the SUNA will sample for.

When the SUNA is powered, the instrument will begin it’s programmed sampling mode on the hour. Users can use the offset feature to change the start time. For example, an offset value of 300 (5 min) changes the start time by five minutes, for example, from 06:00 p.m. to 06:05 p.m.

Temperature and Conductivity are two of the most important values taken into consideration when our instrument calculates the practical salinity of seawater. When one sees a change in a measured value, such as temperature, that change will affect your salinity reading in a predictable way, assuming all else is equal. For instance, in an environment where temperature has begun to drift downward you will see a resulting drift of salinity towards being saltier.

Proper cleaning procedures, allowing your CTD to equilibrate at the surface before a profile, updating your calibrations yearly, and bio-fouling prevention are some ways that you can ensure that your instrument will provide accurate salinity data.

For a more comprehensive look at our salinity calculations please refer to App Note 14, which is hosted on our website.

Cells that have been contaminated with foreign material generally read low of the actual conductivity. Your zero (in air) conductivity reading is generally unaffected.

The conductivity error due to fouling will generally be proportional to the conductivity value. Conductivity is corrected not as an offset but as a ratio (multiplicative) error compared to a reference.

Salinity is a derivative measurement of temperature, conductivity, and pressure, and should be corrected by adjusting the component measurements. Generally speaking, an error in the conductivity measurement will correlate to a directly proportional error in the salinity measurement.

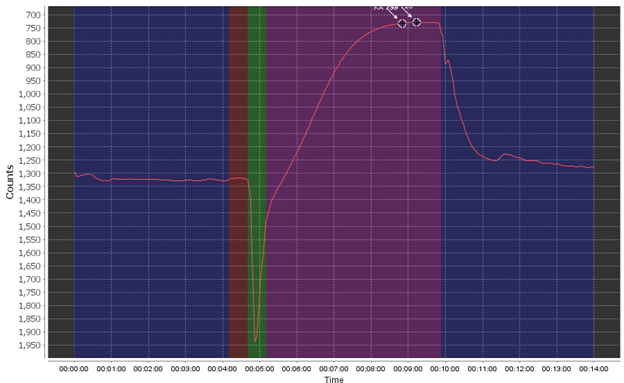

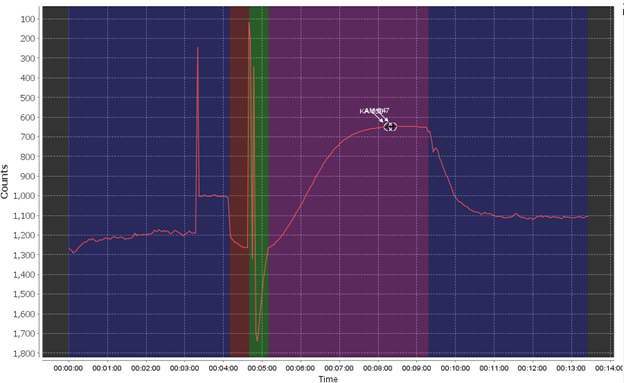

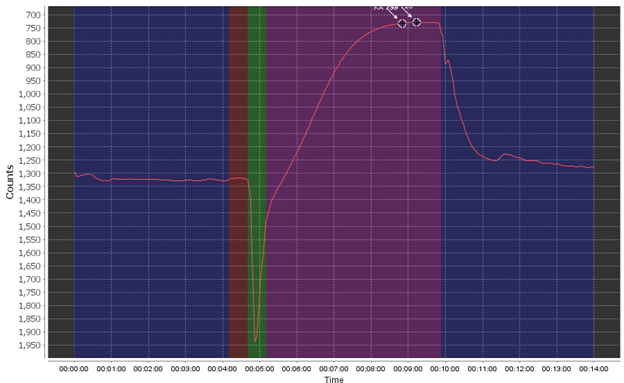

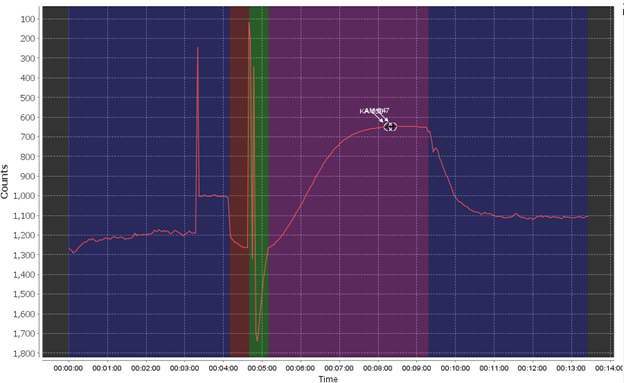

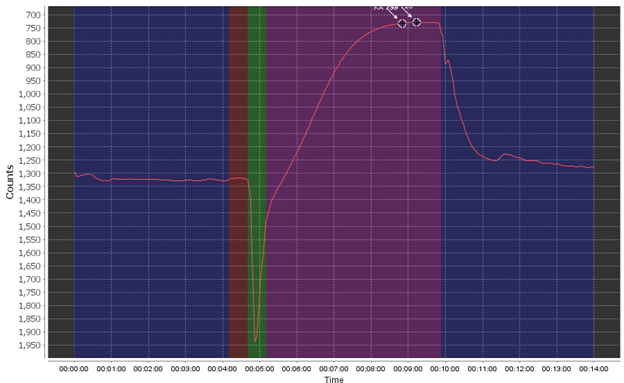

First off, let’s see what a relatively good Raw Data Plot looks like.

The different phases are the pre-flush phase (dark blue), the ambient baseline reading period (red), the sample reagent pump phase (green), the sample read/reaction phase (purple), and finally the post-flush phase (dark blue). During a “spiked run” the full set of phases are repeated twice.

Using this as an example, you want to see a flat pre- and post-pump phase, a stable (flat) ambient read phase, and a pronounced smooth reaction curve. You may see small bumps here and there due to very small bubbles or other effects but this can be negligible.

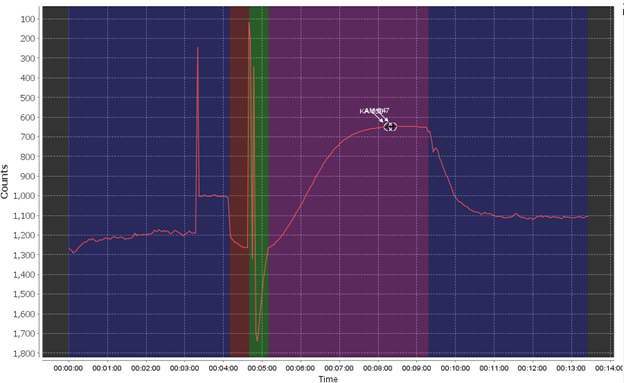

The most common failure mode is the bubble spike flag, which triggers when air is introduced into the system, most commonly through the sample line but possibly through incorrectly installed cartridges or tubing.

The bubble failure is typically identified by large jumps and spikes randomly in the data, primarily in the pre- and post- pump phase and the ambient read phase. Air bubbles create an unstable base line (red) which will affect the sensor’s accuracy. In extreme examples it can completely overshadow the reaction curve as well or shift the baseline to the point where your reaction creates a negative value. Air bubbles often exacerbate other issues, like weak pumps, clogged filters, or already low phosphate in your sample.

Since bubbles can come from a few different places there are multiple checks you can do to try to stop bubbles from appearing in your data. The most important check is ensuring that your hydrocycle is fully submerged for the entirety of your deployment, as the sample line being exposed to air will introduce bubbles.

You should check that each of your reagent carts are fully installed. Press down on each reagent cart until you can hear them click and be careful about applying too much force to any of the plastic pieces that may crack and allow for leaks or air.

You can also test the pump volumes of each reagent and sample to see if your filters are clogged or if there is another issue causing the sample injection system to fail, like a leak. You do so by using Cyclehost’s Pump controls. You should choose all pumps and run each for 100 pumps. A healthy system will pump 1-1.3 ml of reagent and 2.5-3 ml of sample.

If you have bubbles already and need to recover, the most thorough method is to follow our maintenance and cleaning instructions in the manual, primarily the extended flush. Running the extended flush multiple times should be enough to clear bubbles from your system if no other issues are evident.

If doing so still fails to recover your instrument’s counts please reach out to technical support with a copy of your hydrocycle data and brief timeline of events.

Scientific

The pH sensor will be shipped dry but was pre-conditioned in seawater (generally from Pacific Ocean waters near Hawaii). While conditioning and evaluating the pH sensor, only expose it filtered, sterilized natural seawater. Do not use seawater CRMs (Certified Reference Material), synthetic seawater, deionized water, NaCl Solutions, or tap water.

Before pre-deployment testing, you will need to fill the plumbing around the pH sensor with natural seawater. The pH sensor needs time to acclimate to the ionic concentration of region specific waters. Once wet, the time to recondition the sensor so that it will report within its accuracy specification depends on several factors, including the ionic composition of the seawater used and the amount of time the pH sensor was stored dry. This time can range from several hours to up to three days.

When the seawater bridge between Counter Electrode and ISFET is broken for longer than 10 seconds, it will be necessary to re-condition the sensor. The sensor does not require recalibration after being re-conditioned.

To prepare the sensor for deployment, it is recommended that several days prior to deployment, the isolated battery is connected via the float interface and the pH sensor is stored in water that is similar to the deployment site. The sensor should be stored dry to avoid bio-fouling of the ISFET and the battery may be removed during storage. Seawater creates a half cell bridge between the Counter Electrode and ISFET, and power to that circuit is provided by the isolated 9V cell. Without seawater, the battery is unnecessary and may be disconnected.

Cells that have been contaminated with foreign material generally read low of the actual conductivity. Your zero (in air) conductivity reading is generally unaffected.

The conductivity error due to fouling will generally be proportional to the conductivity value. Conductivity is corrected not as an offset but as a ratio (multiplicative) error compared to a reference.

Salinity is a derivative measurement of temperature, conductivity, and pressure, and should be corrected by adjusting the component measurements. Generally speaking, an error in the conductivity measurement will correlate to a directly proportional error in the salinity measurement.

The SeaFET and SeapHOx systems are designed to sample at a fixed depth. If you want to run discreet samples at depth intervals, you will need to find a way to move the system to a specific depth before each sample interval and stop the descent / ascent for the entire pumping and sampling cycle to get a valid CTD / pH / Oxygen sample.

If you are able to communicate with the system through the serial I/O during profiling, you can send a sampling command to the sensor at each depth point and allow it to complete its sample cycle. Consult the manual for each model for the length of time required to complete each sample. Once the sensor provides a sample, you can then move it to the next depth point and repeat.

If you aren’t running real-time communications to the SeaFET/SeapHOx, you could also set it to autonomously sample at a time interval that gives you enough time to move the package to a new depth point between sample cycles. The challenges with this approach would be to know exactly when the sensor is sampling without any direct feedback from the instrument.

SUNAs ordered with the 5mm path length coupler as a factory option will perform much better in low light transmission waters due to the shorter length the light needs to travel leading to less absorption. Equipping your SUNA with the factory bio-wiper option will also perform better and be less susceptible biofouling or buildup of other material that can reduce light transmission.

There are also some maintenance practices and device settings that can give SUNA a better probability of being able to capture enough light for a sample. Enable adaptive integration will trigger the SUNA to increase the lamp on time when light received by the spectrometer is low. It is also important to clean the windows as frequently as possible and monitor lens for scratches. Finally, you want your maximum light spectral counts at the peak wavelength (around 240nm) to be between 45,000 and 55,000 counts in pure or deionized water. This can be viewed in the “Spectra” tab in UCI when sampling or replaying data. If your peak spectrometer output is below 45,000 counts after cleaning the window, you may increase the integration period by 25 to 50 ms if needed (but not more; further changes require a factory recalibration). After adjusting the integration period, always perform a reference spectrum update per the instructions in the SUNA manual.

The ECO-PAR, due to the nature of PAR sensors, cannot be accurately calibrated outside of the Sea-Bird facility. However, there are some functionality tests that can aid in pre-deployment. A bright flashlight can validate whether the instrument sees light at all.

On a bench test one should see between 1000-4000 counts normally with the instrument in the white cap standing up on the benchtop. Use a terminal program to see the raw counts, such as Tera Term, and point a flashlight beam near the white cap. Doing so with a functioning unit will cause the counts to go to approximately a couple of thousand in a hair trigger fashion. It should be possible to decrease the counts on a properly functioning instrument by cupping ones hands around the white cap to shield it from light. It should be easy to get a response of a couple of hundred counts total in doing this. In the field if you shine a flashlight beam directly into the optics will see low level ambient light and it is easy to regulate the output in counts at the low end of the range (less than 1000 counts) when it is functioning normally. If your unit is not properly functioning, it will go from 50-ish to a couple of thousand counts and it will be very difficult or impossible to get an output of a couple of hundred counts. While the ranges of the response may differ between PAR models, these tests can be used with other PAR sensors to verify operation.

There are two optional modifications that can be done to your 9p at our facility (during service or as part of your original order) that will allow the 9p CTD to operate in freshwater deployments. The 9p’s pump will not operate in freshwater without these options.

First, the Modem Pump Control, allows you to control the pump directly, bypassing the requirement for it to see a certain conductivity frequency to activate. (On other CTD’s we can change this conductivity value to allow both freshwater and saltwater).

The second option is the freshwater contact pin, an optional pin modification that allows for the detection of fresh water by the 9p.

First off, let’s see what a relatively good Raw Data Plot looks like.

The different phases are the pre-flush phase (dark blue), the ambient baseline reading period (red), the sample reagent pump phase (green), the sample read/reaction phase (purple), and finally the post-flush phase (dark blue). During a “spiked run” the full set of phases are repeated twice.

Using this as an example, you want to see a flat pre- and post-pump phase, a stable (flat) ambient read phase, and a pronounced smooth reaction curve. You may see small bumps here and there due to very small bubbles or other effects but this can be negligible.

The most common failure mode is the bubble spike flag, which triggers when air is introduced into the system, most commonly through the sample line but possibly through incorrectly installed cartridges or tubing.

The bubble failure is typically identified by large jumps and spikes randomly in the data, primarily in the pre- and post- pump phase and the ambient read phase. Air bubbles create an unstable base line (red) which will affect the sensor’s accuracy. In extreme examples it can completely overshadow the reaction curve as well or shift the baseline to the point where your reaction creates a negative value. Air bubbles often exacerbate other issues, like weak pumps, clogged filters, or already low phosphate in your sample.

Since bubbles can come from a few different places there are multiple checks you can do to try to stop bubbles from appearing in your data. The most important check is ensuring that your hydrocycle is fully submerged for the entirety of your deployment, as the sample line being exposed to air will introduce bubbles.

You should check that each of your reagent carts are fully installed. Press down on each reagent cart until you can hear them click and be careful about applying too much force to any of the plastic pieces that may crack and allow for leaks or air.

You can also test the pump volumes of each reagent and sample to see if your filters are clogged or if there is another issue causing the sample injection system to fail, like a leak. You do so by using Cyclehost’s Pump controls. You should choose all pumps and run each for 100 pumps. A healthy system will pump 1-1.3 ml of reagent and 2.5-3 ml of sample.

If you have bubbles already and need to recover, the most thorough method is to follow our maintenance and cleaning instructions in the manual, primarily the extended flush. Running the extended flush multiple times should be enough to clear bubbles from your system if no other issues are evident.

If doing so still fails to recover your instrument’s counts please reach out to technical support with a copy of your hydrocycle data and brief timeline of events.

Manufacturing

Seabird does not manufacture seacables for scientific winch systems and does not specify or endorse any specific cable material. The entire cable assembly must meet the following criteria: A single or multi-core armored cable up to 10,000 meters (32,800 feet) long; an inner core resistance of up to 350 ohms.

The pH sensor will be shipped dry but was pre-conditioned in seawater (generally from Pacific Ocean waters near Hawaii). While conditioning and evaluating the pH sensor, only expose it filtered, sterilized natural seawater. Do not use seawater CRMs (Certified Reference Material), synthetic seawater, deionized water, NaCl Solutions, or tap water.

Before pre-deployment testing, you will need to fill the plumbing around the pH sensor with natural seawater. The pH sensor needs time to acclimate to the ionic concentration of region specific waters. Once wet, the time to recondition the sensor so that it will report within its accuracy specification depends on several factors, including the ionic composition of the seawater used and the amount of time the pH sensor was stored dry. This time can range from several hours to up to three days.

When the seawater bridge between Counter Electrode and ISFET is broken for longer than 10 seconds, it will be necessary to re-condition the sensor. The sensor does not require recalibration after being re-conditioned.

To prepare the sensor for deployment, it is recommended that several days prior to deployment, the isolated battery is connected via the float interface and the pH sensor is stored in water that is similar to the deployment site. The sensor should be stored dry to avoid bio-fouling of the ISFET and the battery may be removed during storage. Seawater creates a half cell bridge between the Counter Electrode and ISFET, and power to that circuit is provided by the isolated 9V cell. Without seawater, the battery is unnecessary and may be disconnected.

The nominal control voltage for the relay is 12 VDC. However, between 5 – 30 VDC will work, applied to pin 4 relative to the ground pin 2 on the Deep SUNA V2. The voltage can be applied to the relay any time after external power is applied to the instrument for a recommended 100 milliseconds. Unless the relay is already switched on, there should be a very quiet (but audible) click when the relay connects power to the SUNA V2 electronics, and the instrument should enter its boot up cycle.

The purpose of the relay is to keep external power applied to the SUNA with very low quiescent current draw, so the typical use case involves the SUNA constantly powered. If the application includes the ability to switch power to the SUNA effectively then the relay feature isn’t necessary. Regardless of how power cycling to the SUNA is controlled, there should be a power-off period of at least 30 seconds between power-on cycles to ensure that the capacitors that prevent a hard shutdown are allowed to completely discharge and allow the SUNA to boot up properly during the next power-on cycle.

No. The Navis does not have charge monitoring capabilities. Typically information of that nature takes a coulomb counter chip, but the overhead with managing the data and powering such a chip is not a current Navis capability and is not expected to be added in the future.

Ordering

The pH sensor will be shipped dry but was pre-conditioned in seawater (generally from Pacific Ocean waters near Hawaii). While conditioning and evaluating the pH sensor, only expose it filtered, sterilized natural seawater. Do not use seawater CRMs (Certified Reference Material), synthetic seawater, deionized water, NaCl Solutions, or tap water.

Before pre-deployment testing, you will need to fill the plumbing around the pH sensor with natural seawater. The pH sensor needs time to acclimate to the ionic concentration of region specific waters. Once wet, the time to recondition the sensor so that it will report within its accuracy specification depends on several factors, including the ionic composition of the seawater used and the amount of time the pH sensor was stored dry. This time can range from several hours to up to three days.

When the seawater bridge between Counter Electrode and ISFET is broken for longer than 10 seconds, it will be necessary to re-condition the sensor. The sensor does not require recalibration after being re-conditioned.

To prepare the sensor for deployment, it is recommended that several days prior to deployment, the isolated battery is connected via the float interface and the pH sensor is stored in water that is similar to the deployment site. The sensor should be stored dry to avoid bio-fouling of the ISFET and the battery may be removed during storage. Seawater creates a half cell bridge between the Counter Electrode and ISFET, and power to that circuit is provided by the isolated 9V cell. Without seawater, the battery is unnecessary and may be disconnected.

The SeaFET and SeapHOx systems are designed to sample at a fixed depth. If you want to run discreet samples at depth intervals, you will need to find a way to move the system to a specific depth before each sample interval and stop the descent / ascent for the entire pumping and sampling cycle to get a valid CTD / pH / Oxygen sample.

If you are able to communicate with the system through the serial I/O during profiling, you can send a sampling command to the sensor at each depth point and allow it to complete its sample cycle. Consult the manual for each model for the length of time required to complete each sample. Once the sensor provides a sample, you can then move it to the next depth point and repeat.

If you aren’t running real-time communications to the SeaFET/SeapHOx, you could also set it to autonomously sample at a time interval that gives you enough time to move the package to a new depth point between sample cycles. The challenges with this approach would be to know exactly when the sensor is sampling without any direct feedback from the instrument.

The nominal control voltage for the relay is 12 VDC. However, between 5 – 30 VDC will work, applied to pin 4 relative to the ground pin 2 on the Deep SUNA V2. The voltage can be applied to the relay any time after external power is applied to the instrument for a recommended 100 milliseconds. Unless the relay is already switched on, there should be a very quiet (but audible) click when the relay connects power to the SUNA V2 electronics, and the instrument should enter its boot up cycle.

The purpose of the relay is to keep external power applied to the SUNA with very low quiescent current draw, so the typical use case involves the SUNA constantly powered. If the application includes the ability to switch power to the SUNA effectively then the relay feature isn’t necessary. Regardless of how power cycling to the SUNA is controlled, there should be a power-off period of at least 30 seconds between power-on cycles to ensure that the capacitors that prevent a hard shutdown are allowed to completely discharge and allow the SUNA to boot up properly during the next power-on cycle.

SUNAs ordered with the 5mm path length coupler as a factory option will perform much better in low light transmission waters due to the shorter length the light needs to travel leading to less absorption. Equipping your SUNA with the factory bio-wiper option will also perform better and be less susceptible biofouling or buildup of other material that can reduce light transmission.

There are also some maintenance practices and device settings that can give SUNA a better probability of being able to capture enough light for a sample. Enable adaptive integration will trigger the SUNA to increase the lamp on time when light received by the spectrometer is low. It is also important to clean the windows as frequently as possible and monitor lens for scratches. Finally, you want your maximum light spectral counts at the peak wavelength (around 240nm) to be between 45,000 and 55,000 counts in pure or deionized water. This can be viewed in the “Spectra” tab in UCI when sampling or replaying data. If your peak spectrometer output is below 45,000 counts after cleaning the window, you may increase the integration period by 25 to 50 ms if needed (but not more; further changes require a factory recalibration). After adjusting the integration period, always perform a reference spectrum update per the instructions in the SUNA manual.

There are several considerations when determining whether the deck box and CTD underwater unit will be compatible.

(1) In most cases (with the exception being (2), below), instruments with the “-plus” designation are compatible with each other, but the “-plus” variants are not compatible with the variants that do not have “-plus” in their model number (i.e., an SBE9plus CTD must be used with an SBE11plus, and cannot be used with an older SBE11 deck unit).

(2) If you have an SBE9/11plus system with the serial uplink feature installed, then both the deck box and the CTD must have the same hardware configuration from the factory (either enabled or disabled). Otherwise, no telemetry will be received from the CTD by the deck box.

(3) For older instruments that do not have “-plus” in their model number, you need a matching pair of SBE9 and SBE11. There was no standard configuration, and different CTDs and deck units could have telemetry word/rate differences (4/24, 8/24, 12/24, etc.) and power differences (standard low power or high power). You would need to consult the original documentation that shipped with the instruments or send them to Sea-bird service for a repair evaluation to determine compatibility.

Service

High humidity is often signs of a leak- the SUNA V2 is sealed at the factory and is not meant to be opened outside of service, and an internal desiccant should prevent any moisture left over after assembly from affecting the electronics. In the case that your self test generated by UCI reports back a humidity higher than 30%, or a steady upwards trend over the course of your deployment.

As to the effects of high humidity, it is likely to cause:

– condensation to form on the inner surface of the optics window, under certain ambient conditions. This dramatically impacts the optics and will prevent you from collecting reasonable data.

– corrosion on internal connections and electronics boards, stressing the lamp function and spectrometer. Intense corrosion will lead to equipment failure.

It is difficult to know the time-frame under which the humidity conditions will affect the instrument, so, we recommend getting the SUNA serviced as soon as the humidity reaches about 30%. If you notice any concerning trends, reach out to the support team for recommendations.

The pH sensor will be shipped dry but was pre-conditioned in seawater (generally from Pacific Ocean waters near Hawaii). While conditioning and evaluating the pH sensor, only expose it filtered, sterilized natural seawater. Do not use seawater CRMs (Certified Reference Material), synthetic seawater, deionized water, NaCl Solutions, or tap water.

Before pre-deployment testing, you will need to fill the plumbing around the pH sensor with natural seawater. The pH sensor needs time to acclimate to the ionic concentration of region specific waters. Once wet, the time to recondition the sensor so that it will report within its accuracy specification depends on several factors, including the ionic composition of the seawater used and the amount of time the pH sensor was stored dry. This time can range from several hours to up to three days.

When the seawater bridge between Counter Electrode and ISFET is broken for longer than 10 seconds, it will be necessary to re-condition the sensor. The sensor does not require recalibration after being re-conditioned.

To prepare the sensor for deployment, it is recommended that several days prior to deployment, the isolated battery is connected via the float interface and the pH sensor is stored in water that is similar to the deployment site. The sensor should be stored dry to avoid bio-fouling of the ISFET and the battery may be removed during storage. Seawater creates a half cell bridge between the Counter Electrode and ISFET, and power to that circuit is provided by the isolated 9V cell. Without seawater, the battery is unnecessary and may be disconnected.

Cells that have been contaminated with foreign material generally read low of the actual conductivity. Your zero (in air) conductivity reading is generally unaffected.

The conductivity error due to fouling will generally be proportional to the conductivity value. Conductivity is corrected not as an offset but as a ratio (multiplicative) error compared to a reference.

Salinity is a derivative measurement of temperature, conductivity, and pressure, and should be corrected by adjusting the component measurements. Generally speaking, an error in the conductivity measurement will correlate to a directly proportional error in the salinity measurement.

The primary maintenance procedures that are outlined in the manual are for the bio-wiper (shutter) installation, the internal battery replacement and the bulkhead connector inspection. The shutter replacement is not always necessary; however, having the copper shutter and face plate parts available to swap out as needed is a good idea.

Otherwise, the optics face should be inspected for film/streaks. The wiper may not work effectively if the copper faceplate condition deteriorates and damages the rubber blade. Some environmental conditions can start to “pit” the face plate surface, shredding the wiper blade. Replacing the face plate should be done if the wiper blade is getting damaged by being dragged across it. Otherwise, cleaning the active optics sensor area usually only requires DI water and a lab wipe (i.e. Kimwipe). Superficial scrapes and scratches on the optics face are unlikely to significantly affect the measurement.

Working with the shutter, moving it for inspection and/or removing it to install a new one, requires the instrument to be powered ON… keeping power to the shutter motor and commanding the open/close positions via software command/control. When moving/removing the shutter, it should NOT BE MOVED MANUALLY! There are gears in the ECO shutter motor that can strip easily with the wrong manual motion, unpowered. The manual motion in the wrong direction and speed, can overcome some of the gear ratios at play when they are back-driven.

Terminal emulator programs (as opposed to ECO View) are the most direct platform for working with the ECO’s. However, their use depends on one’s preference for how to interface with the instruments.

SUNAs ordered with the 5mm path length coupler as a factory option will perform much better in low light transmission waters due to the shorter length the light needs to travel leading to less absorption. Equipping your SUNA with the factory bio-wiper option will also perform better and be less susceptible biofouling or buildup of other material that can reduce light transmission.

There are also some maintenance practices and device settings that can give SUNA a better probability of being able to capture enough light for a sample. Enable adaptive integration will trigger the SUNA to increase the lamp on time when light received by the spectrometer is low. It is also important to clean the windows as frequently as possible and monitor lens for scratches. Finally, you want your maximum light spectral counts at the peak wavelength (around 240nm) to be between 45,000 and 55,000 counts in pure or deionized water. This can be viewed in the “Spectra” tab in UCI when sampling or replaying data. If your peak spectrometer output is below 45,000 counts after cleaning the window, you may increase the integration period by 25 to 50 ms if needed (but not more; further changes require a factory recalibration). After adjusting the integration period, always perform a reference spectrum update per the instructions in the SUNA manual.

There are several considerations when determining whether the deck box and CTD underwater unit will be compatible.

(1) In most cases (with the exception being (2), below), instruments with the “-plus” designation are compatible with each other, but the “-plus” variants are not compatible with the variants that do not have “-plus” in their model number (i.e., an SBE9plus CTD must be used with an SBE11plus, and cannot be used with an older SBE11 deck unit).

(2) If you have an SBE9/11plus system with the serial uplink feature installed, then both the deck box and the CTD must have the same hardware configuration from the factory (either enabled or disabled). Otherwise, no telemetry will be received from the CTD by the deck box.

(3) For older instruments that do not have “-plus” in their model number, you need a matching pair of SBE9 and SBE11. There was no standard configuration, and different CTDs and deck units could have telemetry word/rate differences (4/24, 8/24, 12/24, etc.) and power differences (standard low power or high power). You would need to consult the original documentation that shipped with the instruments or send them to Sea-bird service for a repair evaluation to determine compatibility.

Field Procedures & Deployment

The SUNA V2 has capacitors that maintain internal power for to the electronics long enough for a proper shutdown process when external power is removed. However, these capacitors must completely discharge between power cycles, or else the SUNA may fail to properly boot up when external power is reapplied. If your SUNA is stuck in a state where it will not respond to external power, unplug the bulkhead connector completely from the SUNA and wait 30-60 seconds before reapplying external power again.

The polled mode setting allows the user to program the SUNA to sample when a command is sent. Customers who would like to integrate an SDI-12 controller with their SUNA should use the polled mode setting. Please note that the SDI-12 operation is not available on SUNA V2 Deep sensors.

Unfortunately, users cannot currently program their SUNA to start at a preferred time. As soon as the SUNA is powered, the instrument will begin it’s programmed sampling mode on the hour. Users can use the offset feature to change the start time. For example, an offset value of 300 (5 min) changes the start time by five minutes, for example, from 06:00 to 06:05.

The continuous mode setting allows the user to program their SUNA to run continuously for an indefinite amount of time. When power is supplied to the SUNA, it will start data acquisition without an end time or maximum number of frames to measure. In general, we do not recommend this mode for long periods of time because the lamp of the SUNA can burn out. As a general rule of thumb, the SUNA lamp should be replaced when it reaches 750 hours.

The periodic mode setting allows the user to select how often, and how long sample intervals are based on frame-based or time-based operation.

For example, if a user would like to program their SUNA to sample every two hours, they would use a sample interval of two hours.

The user would then select either frame-based or time-based operation

For frame-based operation, the user selects the number of light frames the SUNA will sample for.

For time-based operation the user selects how many seconds of light frames the SUNA will sample for.

When the SUNA is powered, the instrument will begin it’s programmed sampling mode on the hour. Users can use the offset feature to change the start time. For example, an offset value of 300 (5 min) changes the start time by five minutes, for example, from 06:00 p.m. to 06:05 p.m.

High humidity is often signs of a leak- the SUNA V2 is sealed at the factory and is not meant to be opened outside of service, and an internal desiccant should prevent any moisture left over after assembly from affecting the electronics. In the case that your self test generated by UCI reports back a humidity higher than 30%, or a steady upwards trend over the course of your deployment.

As to the effects of high humidity, it is likely to cause:

– condensation to form on the inner surface of the optics window, under certain ambient conditions. This dramatically impacts the optics and will prevent you from collecting reasonable data.

– corrosion on internal connections and electronics boards, stressing the lamp function and spectrometer. Intense corrosion will lead to equipment failure.

It is difficult to know the time-frame under which the humidity conditions will affect the instrument, so, we recommend getting the SUNA serviced as soon as the humidity reaches about 30%. If you notice any concerning trends, reach out to the support team for recommendations.

The SBE9/11+ system does not have the capability to support any instrumentation data or signals via its sea cable that are not directly connected to the SBE9+ CTD and associated carousels.

There is a hardware upgrade on the 9/11+ system that provides a serial RS-232 data uplink. This is a relatively constrained feature on the 9/11+ system, that allows a serial RS-232 data stream to be passed up the sea cable and saved as a separate data file.

NOTE: This upgrade is installed in the 9/11+ at the factory and operates at 9600 baud, requiring

that the 9/11+ be configured/operating at this same baud rate.

None of this is compatible with a video signal to be integrated into this system. Additional hardware components inline with the sea cable that are not supplied by Sea-Bird Scientific would be required. This custom application is not currently supported.

The lifespan of the probe is typically between 3 months and 2 years, depending on where and how often it is deployed, storage conditions, and the particular electrode performance. It is a good idea to periodically check the storage solution to make sure that it is still full, and you can use Parafilm on the bottle cap and store the sensor vertically for best results. Routine checks on performance can help prevent premature sensor drift.

Some indications that we use to evaluate if the electrode needs replacement:

– Physical condition – Sometimes the probe will crystalize and you can see large gaps (air pockets) in the reference electrode, whereas a good probe will be more uniform.

– Slow response time – Another symptom that a probe is going bad. For example, if it takes more than 10-15 minutes to reach a stable pH value, or it might not stabilize at all.

– Poor readings, such as high pH residuals or big changes in raw voltage output. For example, if it reads < 1.7 VDC in pH 4 solution. We look at all of the indications above to make the best determination about whether an electrode needs to be replaced. Generally, the best way to evaluate your pH probe is to calibrate your sensor frequently (such as once a month) using consistent and fresh buffer solutions, and track the change in response time, raw voltage output and pH residuals over time.

Temperature and Conductivity are two of the most important values taken into consideration when our instrument calculates the practical salinity of seawater. When one sees a change in a measured value, such as temperature, that change will affect your salinity reading in a predictable way, assuming all else is equal. For instance, in an environment where temperature has begun to drift downward you will see a resulting drift of salinity towards being saltier.

Proper cleaning procedures, allowing your CTD to equilibrate at the surface before a profile, updating your calibrations yearly, and bio-fouling prevention are some ways that you can ensure that your instrument will provide accurate salinity data.

For a more comprehensive look at our salinity calculations please refer to App Note 14, which is hosted on our website.

In general, the best practice is to store instruments at temperatures above freezing (0 degrees C), and below 35 degrees C (keeping out of direct sunlight while on deck whenever possible).

It is best to minimize exposure at high temperatures, as this could contribute to instrument drift.

At low temperatures, below freezing, the conductivity cell is susceptible to cracking, so it is recommended to store the instrument dry. Note, if the CTD has auxiliary sensors installed, storage recommendations can be found in the appropriate manual for individual sensors. Some instruments must be stored in a liquid solution or in filtered seawater, but this will be made evident in the documentation provided to you upon purchase. It is crucial that these sensors are protected from cold temperatures that may cause these liquids to freeze.

Replacement batteries for the 37 Microcat family are available from multiple retailers online, as Seabird Scientific recommends that Saft AA LS14500 3.6V lithium cells be used as the primary batteries. If this brand is not available in your area please reach out to sales or support for assistance.

Seabird does not manufacture seacables for scientific winch systems and does not specify or endorse any specific cable material. The entire cable assembly must meet the following criteria: A single or multi-core armored cable up to 10,000 meters (32,800 feet) long; an inner core resistance of up to 350 ohms.

The recommended nominal flow rate is 1 liter/second (15.8 gallons/minute).

The pH sensor will be shipped dry but was pre-conditioned in seawater (generally from Pacific Ocean waters near Hawaii). While conditioning and evaluating the pH sensor, only expose it filtered, sterilized natural seawater. Do not use seawater CRMs (Certified Reference Material), synthetic seawater, deionized water, NaCl Solutions, or tap water.

Before pre-deployment testing, you will need to fill the plumbing around the pH sensor with natural seawater. The pH sensor needs time to acclimate to the ionic concentration of region specific waters. Once wet, the time to recondition the sensor so that it will report within its accuracy specification depends on several factors, including the ionic composition of the seawater used and the amount of time the pH sensor was stored dry. This time can range from several hours to up to three days.

When the seawater bridge between Counter Electrode and ISFET is broken for longer than 10 seconds, it will be necessary to re-condition the sensor. The sensor does not require recalibration after being re-conditioned.

To prepare the sensor for deployment, it is recommended that several days prior to deployment, the isolated battery is connected via the float interface and the pH sensor is stored in water that is similar to the deployment site. The sensor should be stored dry to avoid bio-fouling of the ISFET and the battery may be removed during storage. Seawater creates a half cell bridge between the Counter Electrode and ISFET, and power to that circuit is provided by the isolated 9V cell. Without seawater, the battery is unnecessary and may be disconnected.

Cells that have been contaminated with foreign material generally read low of the actual conductivity. Your zero (in air) conductivity reading is generally unaffected.

The conductivity error due to fouling will generally be proportional to the conductivity value. Conductivity is corrected not as an offset but as a ratio (multiplicative) error compared to a reference.

Salinity is a derivative measurement of temperature, conductivity, and pressure, and should be corrected by adjusting the component measurements. Generally speaking, an error in the conductivity measurement will correlate to a directly proportional error in the salinity measurement.

The primary maintenance procedures that are outlined in the manual are for the bio-wiper (shutter) installation, the internal battery replacement and the bulkhead connector inspection. The shutter replacement is not always necessary; however, having the copper shutter and face plate parts available to swap out as needed is a good idea.

Otherwise, the optics face should be inspected for film/streaks. The wiper may not work effectively if the copper faceplate condition deteriorates and damages the rubber blade. Some environmental conditions can start to “pit” the face plate surface, shredding the wiper blade. Replacing the face plate should be done if the wiper blade is getting damaged by being dragged across it. Otherwise, cleaning the active optics sensor area usually only requires DI water and a lab wipe (i.e. Kimwipe). Superficial scrapes and scratches on the optics face are unlikely to significantly affect the measurement.

Working with the shutter, moving it for inspection and/or removing it to install a new one, requires the instrument to be powered ON… keeping power to the shutter motor and commanding the open/close positions via software command/control. When moving/removing the shutter, it should NOT BE MOVED MANUALLY! There are gears in the ECO shutter motor that can strip easily with the wrong manual motion, unpowered. The manual motion in the wrong direction and speed, can overcome some of the gear ratios at play when they are back-driven.

Terminal emulator programs (as opposed to ECO View) are the most direct platform for working with the ECO’s. However, their use depends on one’s preference for how to interface with the instruments.

The SeaFET and SeapHOx systems are designed to sample at a fixed depth. If you want to run discreet samples at depth intervals, you will need to find a way to move the system to a specific depth before each sample interval and stop the descent / ascent for the entire pumping and sampling cycle to get a valid CTD / pH / Oxygen sample.

If you are able to communicate with the system through the serial I/O during profiling, you can send a sampling command to the sensor at each depth point and allow it to complete its sample cycle. Consult the manual for each model for the length of time required to complete each sample. Once the sensor provides a sample, you can then move it to the next depth point and repeat.

If you aren’t running real-time communications to the SeaFET/SeapHOx, you could also set it to autonomously sample at a time interval that gives you enough time to move the package to a new depth point between sample cycles. The challenges with this approach would be to know exactly when the sensor is sampling without any direct feedback from the instrument.

The nominal control voltage for the relay is 12 VDC. However, between 5 – 30 VDC will work, applied to pin 4 relative to the ground pin 2 on the Deep SUNA V2. The voltage can be applied to the relay any time after external power is applied to the instrument for a recommended 100 milliseconds. Unless the relay is already switched on, there should be a very quiet (but audible) click when the relay connects power to the SUNA V2 electronics, and the instrument should enter its boot up cycle.

The purpose of the relay is to keep external power applied to the SUNA with very low quiescent current draw, so the typical use case involves the SUNA constantly powered. If the application includes the ability to switch power to the SUNA effectively then the relay feature isn’t necessary. Regardless of how power cycling to the SUNA is controlled, there should be a power-off period of at least 30 seconds between power-on cycles to ensure that the capacitors that prevent a hard shutdown are allowed to completely discharge and allow the SUNA to boot up properly during the next power-on cycle.

SUNAs ordered with the 5mm path length coupler as a factory option will perform much better in low light transmission waters due to the shorter length the light needs to travel leading to less absorption. Equipping your SUNA with the factory bio-wiper option will also perform better and be less susceptible biofouling or buildup of other material that can reduce light transmission.

There are also some maintenance practices and device settings that can give SUNA a better probability of being able to capture enough light for a sample. Enable adaptive integration will trigger the SUNA to increase the lamp on time when light received by the spectrometer is low. It is also important to clean the windows as frequently as possible and monitor lens for scratches. Finally, you want your maximum light spectral counts at the peak wavelength (around 240nm) to be between 45,000 and 55,000 counts in pure or deionized water. This can be viewed in the “Spectra” tab in UCI when sampling or replaying data. If your peak spectrometer output is below 45,000 counts after cleaning the window, you may increase the integration period by 25 to 50 ms if needed (but not more; further changes require a factory recalibration). After adjusting the integration period, always perform a reference spectrum update per the instructions in the SUNA manual.

There are two ways the Navis float can start a mission without the user explicitly starting pressure activation or mission execute:

(1) Not freezing the float:

If the float is not frozen (I F command) before the communications dongle is removed, the float controller will eventually timeout.

(2) Communications dongle noise:

If the user sends the I F command, then disconnects and the communications dongle, there can be small electrical pulses as the connection is removed that may cause the float to wake back up. The float will then timeout and start a mission. This can be prevented by adding a break switch in-line with the Navis communications dongle that can be turned off before physically disconnecting it from the float.

Both of these events are intentionally implemented as a failsafe in case a user accidentally deployed a float before activating the mission.

No. The Navis does not have charge monitoring capabilities. Typically information of that nature takes a coulomb counter chip, but the overhead with managing the data and powering such a chip is not a current Navis capability and is not expected to be added in the future.

There are several considerations when determining whether the deck box and CTD underwater unit will be compatible.

(1) In most cases (with the exception being (2), below), instruments with the “-plus” designation are compatible with each other, but the “-plus” variants are not compatible with the variants that do not have “-plus” in their model number (i.e., an SBE9plus CTD must be used with an SBE11plus, and cannot be used with an older SBE11 deck unit).

(2) If you have an SBE9/11plus system with the serial uplink feature installed, then both the deck box and the CTD must have the same hardware configuration from the factory (either enabled or disabled). Otherwise, no telemetry will be received from the CTD by the deck box.

(3) For older instruments that do not have “-plus” in their model number, you need a matching pair of SBE9 and SBE11. There was no standard configuration, and different CTDs and deck units could have telemetry word/rate differences (4/24, 8/24, 12/24, etc.) and power differences (standard low power or high power). You would need to consult the original documentation that shipped with the instruments or send them to Sea-bird service for a repair evaluation to determine compatibility.

We do not specify a maximum line resistance. However, the Inductive Modem systems are very tolerant of the resistivity of seawater. It is typically only a consideration when the system is being deployed in freshwater lakes, etc. where the salinity level is a lot lower.

We recommended using one of the two oceanographic cables below or those of equivalent specification:

1. Loos & Co. 3×19 Galvanized Oceanographic Cable, Plastic Impregnated

2. WireCo WorldGroup Macwhyte 3×19 Space-Lay Plastic Impregnated and Coated Wire Rope

The most important aspect is the resilience of the cable jacket. Any cuts, tears, or breaks in the insulation will create a shorter path to the seawater ground which will result in the the level of the signal on the lower side of the cable being attenuated.

Lithium battery packs are not suitable for use with 16plus units that have the 5T or 5M pumps installed as the drain on the battery is significantly higher. This effect causes deployments to be shorter and is not reflected in the SBE Deployment Endurance software, making planning your deployment more difficult.

There are two optional modifications that can be done to your 9p at our facility (during service or as part of your original order) that will allow the 9p CTD to operate in freshwater deployments. The 9p’s pump will not operate in freshwater without these options.

First, the Modem Pump Control, allows you to control the pump directly, bypassing the requirement for it to see a certain conductivity frequency to activate. (On other CTD’s we can change this conductivity value to allow both freshwater and saltwater).

The second option is the freshwater contact pin, an optional pin modification that allows for the detection of fresh water by the 9p.

SUNAs ordered with the 5mm path length coupler as a factory option will perform much better in low light transmission waters due to the shorter length the light needs to travel leading to less absorption. Equipping your SUNA with the factory bio-wiper option will also perform better and be less susceptible biofouling or buildup of other material that can reduce light transmission.

There are also some maintenance practices and device settings that can give SUNA a better probability of being able to capture enough light for a sample. Enable adaptive integration will trigger the SUNA to increase the lamp on time when light received by the spectrometer is low. It is also important to clean the windows as frequently as possible and monitor lens for scratches. Finally, you want your maximum light spectral counts at the peak wavelength (around 240nm) to be between 45,000 and 55,000 counts in pure or deionized water. This can be viewed in the “Spectra” tab in UCI when sampling or replaying data. If your peak spectrometer output is below 45,000 counts after cleaning the window, you may increase the integration period by 25 to 50 ms if needed (but not more; further changes require a factory recalibration). After adjusting the integration period, always perform a reference spectrum update per the instructions in the SUNA manual.

The ECO-PAR, due to the nature of PAR sensors, cannot be accurately calibrated outside of the Sea-Bird facility. However, there are some functionality tests that can aid in pre-deployment. A bright flashlight can validate whether the instrument sees light at all.

On a bench test one should see between 1000-4000 counts normally with the instrument in the white cap standing up on the benchtop. Use a terminal program to see the raw counts, such as Tera Term, and point a flashlight beam near the white cap. Doing so with a functioning unit will cause the counts to go to approximately a couple of thousand in a hair trigger fashion. It should be possible to decrease the counts on a properly functioning instrument by cupping ones hands around the white cap to shield it from light. It should be easy to get a response of a couple of hundred counts total in doing this. In the field if you shine a flashlight beam directly into the optics will see low level ambient light and it is easy to regulate the output in counts at the low end of the range (less than 1000 counts) when it is functioning normally. If your unit is not properly functioning, it will go from 50-ish to a couple of thousand counts and it will be very difficult or impossible to get an output of a couple of hundred counts. While the ranges of the response may differ between PAR models, these tests can be used with other PAR sensors to verify operation.

There are two optional modifications that can be done to your 9p at our facility (during service or as part of your original order) that will allow the 9p CTD to operate in freshwater deployments. The 9p’s pump will not operate in freshwater without these options.

First, the Modem Pump Control, allows you to control the pump directly, bypassing the requirement for it to see a certain conductivity frequency to activate. (On other CTD’s we can change this conductivity value to allow both freshwater and saltwater).

The second option is the freshwater contact pin, an optional pin modification that allows for the detection of fresh water by the 9p.

Oftentimes one will see data in their cast that looks erroneous or out of spec, but reviewing the timeline of each cast and the events which transpired can explain these jumps. If you are starting your cast while your CTD is on deck then the time during which the unit is running in air can be spiky or erratic, but this should be solved after the unit has been fully submerged and the pump has activated. The pump on time setting controls how fast the system will turn on the pump after deployment, so filtering out your deckside data can be done by calculating the number of scans to exclude using your pump on time setting, samples to average setting, and native sampling rate of your CTD.

Bubbles in the flow line can also cause spikes in your data towards the start of your deployment if the system isn’t able to normalize at the surface. We typically recommend units stay near the surface for 2-5 minutes in order to allow air bubbles to escape.

Finally, for additional resources in troubleshooting and smoothing data outliers for your CTD data, refer to our documentation on Seabird University.

The primary maintenance procedures that are outlined in the manual are for the bio-wiper (shutter) installation, the internal battery replacement and the bulkhead connector inspection. The shutter replacement is not always necessary, but, having the copper shutter and face plate parts available to swap out as needed, is a good idea.

Otherwise, the optics face should be inspected for film/streaks. The wiper may not work effectively if the copper faceplate condition deteriorates and damages the rubber blade. Some environmental conditions can start to “pit” the face plate surface, shredding the wiper blade. Replacing the face plate should be done if the wiper blade is getting damaged by being dragged across it. Otherwise, cleaning the active optics sensor area usually only requires DI water and a lab wipe (i.e. Kimwipe). Superficial scrapes and scratches on the optics face are unlikely to significantly affect the measurement.

Working with the shutter, moving it for inspection and/or removing it to install a new one, requires the instrument to be powered ON… keeping power to the shutter motor and commanding the open/close positions via software command/control. When moving/removing the shutter, it should NOT BE MOVED MANUALLY! There are gears in the ECO shutter motor that can strip easily with the wrong manual motion, unpowered. The manual motion in the wrong direction and speed, can overcome some of the gear ratios at play when they are back-driven.

Terminal emulator programs (as opposed to ECO View) are the most direct platform for working with the ECO’s. However, their use depends on one’s preference for how to interface with the instruments.

There are several considerations when determining whether the deck box and CTD underwater unit will be compatible.nn(1) In most cases (with the exception being (2), below), instruments with the “-plus” designation are compatible with each other, but the “-plus” variants are not compatible with the variants that do not have “-plus” in their model number (i.e., an SBE9plus CTD must be used with an SBE11plus, and cannot be used with an older SBE11 deck unit).nn(2) If you have an SBE9/11plus system with the serial uplink feature installed, then both the deck box and the CTD must have the same hardware configuration from the factory (either enabled or disabled). Otherwise, no telemetry will be received from the CTD by the deck box.nn(3) For older instruments that do not have “-plus” in their model number, you need a matching pair of SBE9 and SBE11. There was no standard configuration, and different CTDs and deck units could have telemetry word/rate differences (4/24, 8/24, 12/24, etc.) and power differences (standard low power or high power). You would need to consult the original documentation that shipped with the instruments or send them to Sea-bird service for a repair evaluation to determine compatibility.

The pH sensor will be shipped dry but was pre-conditioned in seawater (generally from Pacific Ocean waters near Hawaii). While conditioning and evaluating the pH sensor, only expose it filtered, sterilized natural seawater. Do not use seawater CRMs (Certified Reference Material), synthetic seawater, deionized water, NaCl Solutions, or tap water.nnBefore pre-deployment testing, you will need to fill the plumbing around the pH sensor with natural seawater. The pH sensor needs time to acclimate to the ionic concentration of region specific waters. Once wet, the time to recondition the sensor so that it will report within its accuracy specification depends on several factors, including the ionic composition of the seawater used and the amount of time the pH sensor was stored dry. This time can range from several hours to up to three days.nnWhen the seawater bridge between Counter Electrode and ISFET is broken for longer than 10 seconds, it will be necessary to re-condition the sensor. The sensor does not require recalibration after being re-conditioned. nnTo prepare the sensor for deployment, it is recommended that several days prior to deployment, the isolated battery is connected via the float interface and the pH sensor is stored in water that is similar to the deployment site. The sensor should be stored dry to avoid bio-fouling of the ISFET and the battery may be removed during storage. Seawater creates a half cell bridge between the Counter Electrode and ISFET, and power to that circuit is provided by the isolated 9V cell. Without seawater, the battery is unnecessary and may be disconnected.

There are two ways the N2 can start a mission without the user explicitly starting pressure activation or mission execute.nnNot Freezing the float:nIf the float is not frozen (I F command) and the dongle is removed, the N2 will eventually timeout. This is more of a precaution in the case the user forgot to start the mission and deployed the float. nnDongle Noise:nIf the user sends the I F command, then attempts to disconnect and the dongle removal is not clean, this may cause the float to wake back up. The float will then timeout and start a mission. Here it would be recommended that a switch is added inline to the dongle (similar to what we have in production)

The only warning of eventual failure is that prior to full battery depletion, the float will typically see a voltage drop with 5-15% of the float life remaining.

This issue can have a few different causes. The most common cause is noise from your Data I/O connector on your CTD. This noise can be caused by a shorted serial deployment cable or water intrusion under the dummy plug on the I/O connector. nnTo solve this issue, we need to identify what is introducing the noise or causing the bad connection. We first suggest that you check the 6-pin data I/O connector “J3” on the SBE19plusV2 bottom endcap. If you notice it being damp or having any corrosion to the pins, cracked or bent pins, or an improperly fitting seal with the cable, those could all cause these intermittent failures. Next, if there is a Y-cable installed on connector “J3,” perform the same inspection on the 4-pin male connector on the pump/data I/O Y-cable. Again, look for anything out of the ordinary as these are the most common failure points.nnIf these connections seem to be in fine condition, if you have another Y cable available you can attempt to swap this to see if this resolves the issue. If this works, the original Y cable should be discarded and replaced.

Cells that have been contaminated with foreign material generally read low of the actual conductivity. Your zero (in air) conductivity reading is generally unaffected.nnThe conductivity error due to fouling will generally be proportional to the conductivity value. Conductivity is corrected not as an offset but as a ratio (multiplicative) error compared to a reference.nnSalinity is a derivative measurement of temperature, conductivity, and pressure, and should be corrected by adjusting the component measurements. Generally speaking, an error in the conductivity measurement will corellate to a directly proportional error in the salinity measurement.

Wet-pluggable (also referred to as wet-mateable or MCBH) connectors, an option on all of our underwater instruments, may be mated in wet conditions (click here for a photo comparison). Their pins do not need to be dried before mating. By design, water on the connector pins is forced out as the connector is mated. However, they must not be mated or un-mated while submerged. Wet-pluggable connectors have a non-conducting guide pin to assist pin alignment & require less force to mate, making them easier to mate reliably under dark or cold conditions, compared to our Impulse XSG/RMG connectors (XSG/RMG connectors may not seal well in extreme cold; we recommend connecting cables in warm ship’s lab rather than on deck for these conditions). Like XSG/RMG connectors, wet-pluggables need proper lubrication & require care during use to avoid trapping water in sockets.

Wet-pluggable connectors do add additional cost to the instrument. The increase in price is dependent on the number of pins on each connector, and the number of connectors on your instrument. When should you consider configuring your instrument with wet-pluggable connectors? Consider the following guidelines:

- Internal recording with a profiling CTD (for example, SBE 9plus with 17plus V2, SBE 19plus V2, SBE 25plus) — Connecting/disconnecting frequently to the CTD is typical for these systems, for uploading of the internally recorded data. Wet-pluggable connectors are recommended for these applications.

- Autonomous water sampling (SBE 32 Carousel with AFM or 17plus V2, or SBE 55 ECO Water Sampler) and internal recording with a profiling CTD — Connecting/disconnecting to the underwater electronics is required after every cast, to re-arm the electronics for autonomous water sampling. Connecting/disconnecting is often done on deck, where the connectors are exposed to splashing and rain; wet-pluggable connectors are strongly recommended for these applications.

- Real-time data acquisition with a profiling CTD (for example, SBE 9plus with 11plus Deck Unit, SBE 19plus V2 with PDIM and SBE 33 or 36 Deck Unit, SBE 25plus with PDIM and SBE 33 or 36 Deck Unit) — The underwater units in these systems are plugged into the sea cable, and typically are disconnected infrequently. Wet-pluggable connectors are not as important for this application.

- Moored instruments —

— If data upload after recovery will occur on deck to allow for quick redeployment, wet-pluggable connectors are recommended.

— If data upload after recovery will occur in a lab, wet-pluggable connectors are not as important for this application.

Note: Prior to 2005, the wet-pluggable connectors available had a rubber-to-metal seal that could break down with prolonged use (3 – 5 years); seal breakdown will lead to instrument flooding. Sea-Bird recommended frequent inspection of the connectors for damage. We also discouraged the use of wet-pluggable connectors for moored deployments, because they cannot be inspected during a prolonged deployment.

From 2005 to 2007, Sea-Bird transitioned to the WB (water block) type of wet-pluggable connectors. WB connectors have a water block that minimizes the possibility of instrument flooding; we do not discourage the use of these types of connectors for moored deployments. If you have wet-pluggable connectors on your instrument and are unsure of which type you have, contact Sea-Bird.

The base sensing suite includes a FastCat CTD, a combined fluorescence and turbidity sensor, and a PAR sensor. The current supported list of instruments for Thetis include:

- CTD: SeaBird FastCat CTD (SBE49)

- Dissolved oxygen: SeaBird SBE43 or SBE63

- Chlorophyll: Sea-Bird Scientific ECO or WETStar series

- CDOM: Sea-Bird Scientific ECO or WETStar series

- Turbidity: Sea-Bird Scientific ECO series

- Optical absorption and attenuation: Sea-Bird Scientific ACS

- PAR: ECO PARS (Sea-Bird Scientific)

- Nitrate: Satlantic SUNA V2

- Irradiance and Radiance: Satlantic OCR and HOCR

- 3-axis velocity: NortekUSA Aquadopp

Additional sensors can be accommodated but may require NRE. Sensors requiring flow though (pumped) measurements can be accommodated with our system.

The mounting system used for the instruments facilitates replacing sensors by the user. Adding new instruments may require new brackets.

The most complete backup system would be another SBE 9plus, to allow for very rapid system swaps. This is important if your stations are close together and there is limited time between CTD casts. However, it is the most expensive option.

The next step down would be an SBE 9plus without sensors. In this case, a system failure would require swapping sensors and pumps to the new unit. This is not difficult, but it is somewhat time consuming. If you have several hours between casts it should not be a problem.

The next option would be to carry spare boards and try and troubleshoot the problem and replace boards. If you have a technician that can do this it is not a bad option. However, it requires some clean and dry lab space to open the CTD and work. You will also have to properly re-seal the CTD. Based upon experience, the SBE 9plus does not fail very often. The most common failure is the main DC-to-DC converter. Other than that, there are very few system failures. However, there are several components that can be damaged through mistakes or misuse. The most catastrophic, other that losing the whole CTD, is to plug the sea cable into the bottom contact connector on the bottom end cap; if this happens, several circuit boards will be destroyed (Note: In 2007 Sea-Bird began using a female bulkhead connector on the 9plus for the bottom contact switch, to differentiate from the sea cable connector and prevent this error. If desired, older CTDs can be retrofitted with the female connector.).

If the budget allows it, we recommend getting a complete backup SBE 9plus, including sensors. If there is any problem, return the malfunctioning instrument for repair and continue sampling with the spare instrument. A complete backup also provides you with spare sensors, so you can rotate 1 set through calibration and continue to operate.

We recommend keeping the connectors on your meter lubricated using a good quality silicone spray lubricant, such as 3M Silicone Spray or Loctite 8021 spray. These can be purchased at your local hardware store. Avoid silicone grease. It is messy and attracts contaminants.

Do not use WD-40. It will destroy connectors.

General

Large numbers of Sea-Bird conductivity instruments have been used in Arctic and Antarctic programs.

Special accommodation to keep temperature, conductivity, oxygen, and optical sensors at or above 0 C is advised. Often, the CTD is brought inside protective doors between casts to achieve this.

Conductivity Cell

When freezing is possible, we recommend that the conductivity sensor be stored dry. Remove larger droplets of water by blowing through the cell. Do not use compressed air, which typically contains oil vapor. Attach a length of Tygon tubing to each end of the conductivity cell to close the cell ends. See Application Note 2D: Instructions for Care and Cleaning of Conductivity Cells for details.

There are several considerations to weigh when contemplating deployments at low temperatures in general, and in frazil or pancake ice:

- Ensure that the instrument is at or above water temperature before it is deployed. If the cell gets colder than 0 to -2 ºC while on deck, when it enters the water a layer of ice forms inside the cell as the cell warms to ocean temperature. If ice forms inside the conductivity cell, measurements will be low of correct until the ice layer melts and disappears. Thin layers of ice will not hurt the conductivity cell, but repeated ice formation on the electrodes will degrade the conductivity calibration (at levels of 0.001 to 0.020 psu) and thicker layers of ice can lead to glass fracture and permanent damage of the cell.

- For accurate measurements, keep ice out of the sensing region of the conductivity cell. The conductivity measurement involves determining the electrical resistance of the water inside the sensor. Ice is essentially a non-conductor. To the extent that ice displaces the water, the conductivity will register (very) misleadingly low. Some type of screening is necessary to keep ice out of the cell. This is relatively easy to arrange for the Sea-Bird conductivity cell, which is an electrode-type cell, because its sensing region is totally inside a long tube; plastic mesh could be positioned at each end and would have zero effect on accuracy and stability.

The above considerations apply to all known conductivity sensor types, whether electrode or inductive types.

If deploying at low temperatures but no surface frazil or pancake ice is present, rinse the conductivity cell in one of the following salty solutions (salty water depresses the freezing point) to prevent freezing during deployment. But this does not mean you can store the cell in one of these solutions outside . . . it will freeze.

- Solution of 1% Triton in sterile seawater (use 0.5-micron filtered seawater or boiled seawater), or

- Brine solution (distilled seawater or homemade salt solution that is higher than 35 psu in salinity).

Note that there is still a risk of forming ice inside the conductivity cell if deploying through frazil or pancake ice on the surface, if the freezing point of the salt water is the same as the water temperature. Therefore, we recommend that you deploy the conductivity cell in a dry state for these deployments.

Commercially available alcohol or glycol antifreezes contain trace amounts of oils that will coat the conductivity cell and the electrodes, causing a calibration shift, and consequently result in errors in the data. Do not use alcohol or glycol in the conductivity cell.

Temperature Sensor

In general, neither the accuracy of the temperature measurement nor the survival of the temperature sensor will be affected by ice.

Oxygen Sensor

For the SBE 43 and SBE 63 Dissolved Oxygen sensor, avoid prolonged exposure to freezing temperature, including during shipment. Do not store with water (fresh or seawater), Triton solution, alcohol, or glycol in the plenum. The best precaution is to keep the sensor indoors or in some shelter out of the cold weather.

Yes, the SeaFET™ pH sensor comes with a flow through cell with fittings that can be plumbed with a pump for flow-through operations. For in situ deployments, we recommend the SBE 5P submersible pump.

Inspecting and Cleaning O-Rings and Mating Surfaces:

- Remove any water from the o-rings and mating surfaces with a lint-free cloth or tissue.

- Visually inspect the o-rings and mating surfaces for dirt, nicks, cuts, scratches, lint, hair, and any signs of corrosion; these could cause the seal to fail. Clean the surfaces, and clean or replace the o-rings as necessary.

- Apply a light, even coat of 100% silicon o-ring lubricant (Parker Super O Lube) to the o-rings and mating surfaces. For an end cap o-ring, a ball of lubricant the size of a pea is about all that is needed. Too much lubricant can cause the seal to fail as much, if not more, than no grease. Do not use petroleum-based lubricant (car grease, Vaseline, etc.), as it will cause premature failure of the rubber.

CAUTION: Parker makes another product, Parker O Lube, that is petroleum-based. Do not use this product; verify that you are using Parker Super O Lube. - After lubricating the o-ring, immediately reassemble the end cap or connector, verifying that no hairs or lint have collected on the lubricated o-ring.

Replacing O-Rings:

- End Cap O-Rings: We recommend scheduled replacement of end cap o-rings approximately every 3 years, to prevent leaks caused by normal o-ring wear.

- Connector O-Rings: Replacing connector o-rings requires de-soldering and re-soldering the connector wires, which makes it a more difficult task. Therefore, we recommend replacement of connector o-rings when needed, not on a routine, scheduled basis.

Additional Information:

- 9-minute video covering O-ring, connector, and cable maintenance.

- Short, silent video of application of lubricant to o-ring.

- Short, silent video of application of lubricant to o-ring mating surface (note the use of a plastic dental syringe— no sharp points to scratch the housing — to apply the lubricant).

“The requirements of a GPS to enable data collection with Sea-Bird Scientific’s SatView software are:

1. NMEA 0183 Output

2. Serial connection The SAS GPS option includes a prewired Garmin model GPS 17xHVS. This model is designed for marine use, and connects to serial port on your computer. It can be mounted to a pole for the duration of the cruise.

A suitable hand held model, is the GPS 72H from Garmin and has both the NEMA output and a serial connection. A optional serial cable is required, and also a power cable, if running from an external power source is desired.”

Mating and Unmating Connectors:

It is important to prepare and mate connectors correctly, both in terms of the costs to repair them and to preserve data quality. Leaking connectors cause noisy data and even potential system shutdowns. Application Note 57: Connector Care and Cable Installation describes the proper care and installation of connectors for Sea-Bird instruments. The Application Note covers connector cleaning and cable or dummy plug installation, locking sleeve installation, and cold weather tips.

Checking for Leakage and Cleaning Corrosion on Connectors:

If there has been leakage, it will show up as green-colored corrosion product. Performing the following steps can usually reverse the effect of the leak:

- Thoroughly clean the connector with water, followed by alcohol.

- Give the connector surfaces a light coating of silicon grease.

Re-mate the connectors properly — see Application Note 57: Connector Care and Cable Installation and 9-minute video covering O-ring, connector, and cable maintenance.

Replacing Connectors:

- The main concern when replacing a bulkhead connector is that the o-rings on the connector and end cap must be prepared and installed correctly; if they are not, the instrument will flood. See the question below for general procedure on handling o-rings.

- Use a thread-locking compound on the connector threads to prevent the new connector from loosening, which could also lead to flooding.

- If the cell guard must be removed to open the instrument, take extra care not to break the glass conductivity cell.